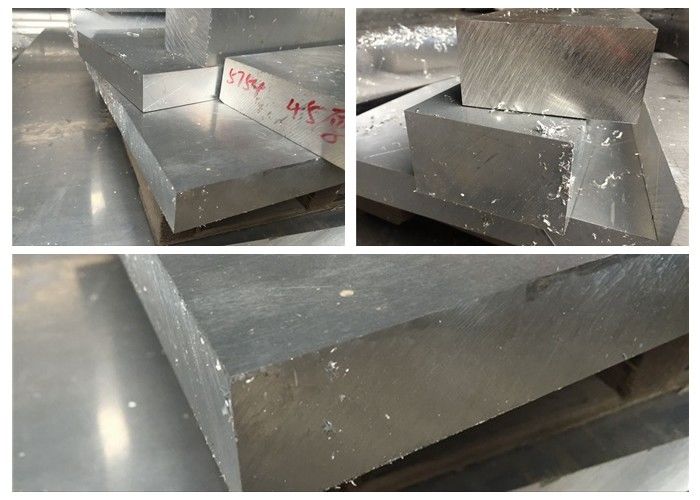

T7651 7075(C775) 18 gauge aluminum plate metal for pipeline vessel tower building.

Quickly details.

1. Alloy: 7075(A-Z5GU) ,7075.

2. Temper: T651,T6

3. Max diameter: 1320mm.

4. Max length : 7500mm.

5. non-standard: 76528 IS 733-2001 IS737-2001.

Application:

7075 alloy aluminum sheet for tower building,

7075 alloy aluminum sheet for vessel,

7075 alloy aluminum sheet for pipeline.

Features:

1. Strong corrosion resistance of high stress structure.

2. 7075 aluminum alloy is a kind of cold treatment forging alloy,

3. 7075 is one of the most powerful alloy commercial.

| (Typical Mechanical Properties) |

|

|

|

|

| ALLOYAND TEMPER |

Ultimate Tensile

Strength,MPa

|

Yield Tensile

Strength,MPa

|

Hardness,HB |

Elongation,% |

| 7075-T651 |

572 |

503 |

160 |

11 |

| Typical Physical Properties |

|

|

|

|

|

ALLOY AND

TEMPER

|

Average Coefficient Of

Thermal Expansion,(20-100℃)um/m.k

|

Melting Range,℃ |

Electrical Conductivity |

Electrical

Resistivity

|

| 7075-T651 |

23.6 |

475-635 |

33 |

0.0515 |

7 Series aluminum alloy is Al - zinc - 3.7 - Cu Mg superhard aluminium, the alloy is in the late 1940 s has been applied in aircraft manufacturing industry, is still widely used in aviation industry deformation of ultra high strength aluminum alloy. Its characteristic is that after solid solution treatment and plastic, heat treatment reinforcement effect is very good, under 150 ℃ has high strength, and has very good strength at low temperature; Welding performance is poor; There is stress corrosion cracking tendency; Need to the package aluminum or other protective treatment. Two-stage aging alloy can be improved the ability of resistance to stress corrosion cracking. After annealing and quenching condition of plastic was slightly lower than the same state of 2 a12) was slightly better than that of 7 a04, plank of static fatigue. Notch sensitivity, stress corrosion performance is better than that of 7 a04. Density is 2.85 g/cm3.

Package: wooden pallet.

FAQ:

Q1. Can we come to China visit factory ?

Yes ,you can .

Q2. Can you send us your aerospace grade aluminum plate Certificate?

Yes, we can.

Q3. How long time get the sample

Is 7 days

Q4. How to contact you?

A: Welcome to call us Or Send us a email, your email will be guaranteed reply within 24 hours.-

Q5: How do you quote price ,per ton ,per meter or kg?

A:We provide more than two pricing modes

Q6: Can we accept customize?

Yes,we can.We can manufacture as customer's requirement.You can send the CAD or drawing to us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!